Kryonaut

Product information "Kryonaut"

Kryonaut thermal paste was created especially for the extremely demanding applications and the highest expectations of the overclocking community. Kryonaut is also highly recommended as a top product for critical cooling systems in the industrial environment.

Properties

- designed for Overclocking

- excellent thermal conductivity

- no curing

-

long-term durability

-

no electrical conductivity

-

Available in four sizes: 1g | 1.5ml | 3ml | 10ml

The choice for overclockers

„Kryo" - the greek word for "cold" - also found in the german word for "cryoengineering", suggests that this thermal paste was created especially for cryogenic applications. For the true "Kryonauts" amongst the "extreme overclockers".

Kryonaut uses a special structure, which halts the drying out process at temperatures of up to 80° Celsius. This carrier structure ensures that the nano-aluminum and zinc oxide components of the paste bond optimally, to compensate for unevenness of the component (i.e. the CPU) or the heat sink, thus achieving remarkable heat transfer.

Application

Product information "Kryonaut"

Kryonaut thermal paste was created especially for the extremely demanding applications and the highest expectations of the overclocking community. Kryonaut is also highly recommended as a top product for critical cooling systems in the industrial environment.

Properties

- designed for Overclocking

- excellent thermal conductivity

-

no curing

-

long-term durability

-

no electrical conductivity

-

Available in four sizes: 1g | 1.5ml | 3ml | 10ml

The choice for overclockers

„Kryo" - the greek word for "cold" - also found in the german word for "cryoengineering", suggests that this thermal paste was created especially for cryogenic applications. For the true "Kryonauts" amongst the "extreme overclockers".

Kryonaut uses a special structure, which halts the drying out process at temperatures of up to 80° Celsius. This carrier structure ensures that the nano-aluminum and zinc oxide components of the paste bond optimally, to compensate for unevenness of the component (i.e. the CPU) or the heat sink, thus achieving remarkable heat transfer.

Application

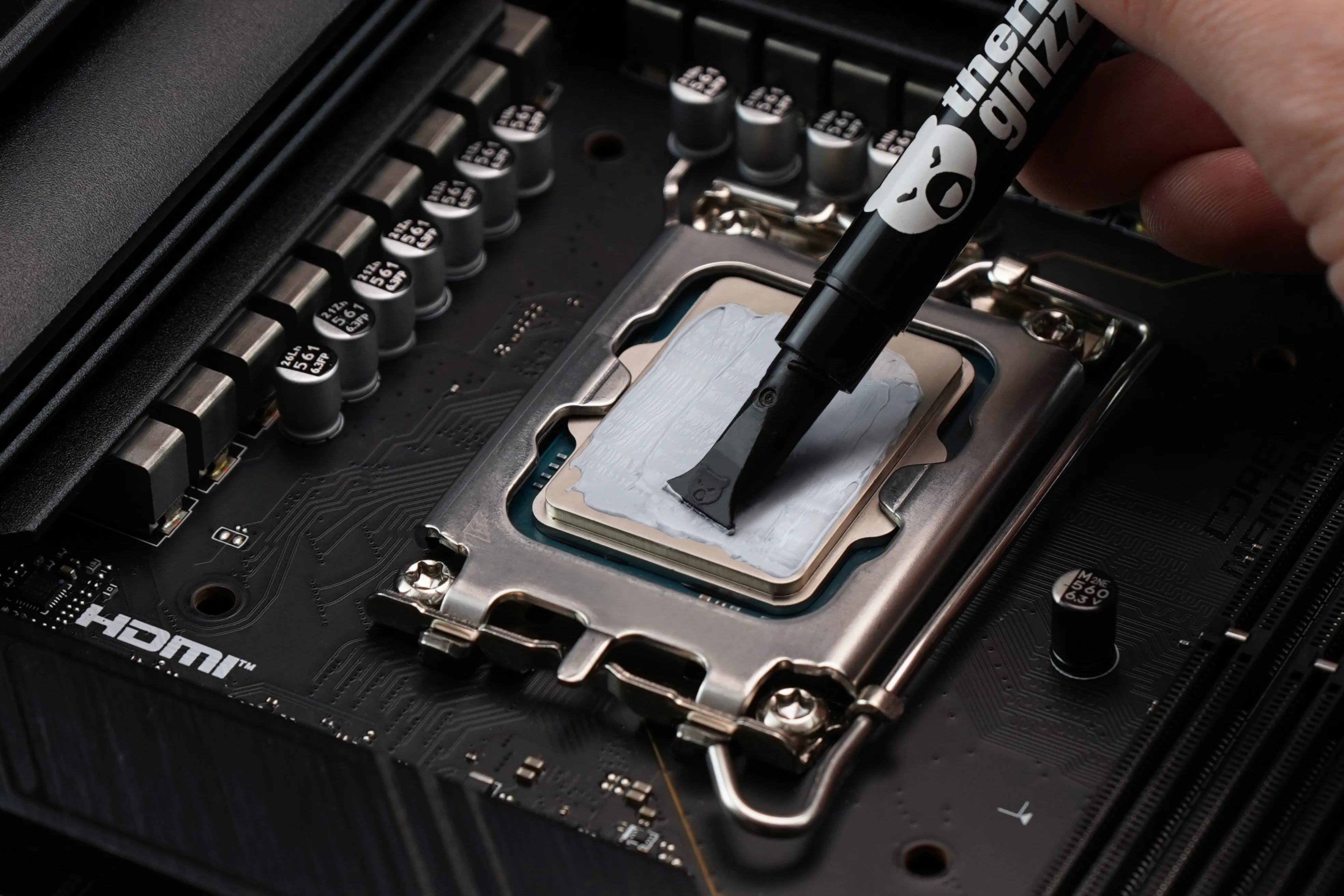

Step 1: Apply a small amount of thermal paste to the CPU

The surface should be thoroughly cleaned and free of grease before use. We recommend using TG Remove or TG Cleaning Wipes for cleaning. When applying, the thermal paste should be at least at room temperature.

Step 2: Spread the thermal paste

When applying, it is important to spread the thermal paste very slowly. On a typical Intel or AMD CPU, a single spreading motion should take about 3 seconds. The slower the movement, the better the paste can be spread.

| Color: | Silver matt |

|---|---|

| Density: | 3.7g/cm³ |

| Electrical conductivity: | 0 pS/m |

| Operating temperature: | -250°C to +350°C |

| Viscosity: | 130 - 170 Pa⋅s |

Goes perfectly with it: